1

/

of

13

Gemma

RUMBA

RUMBA

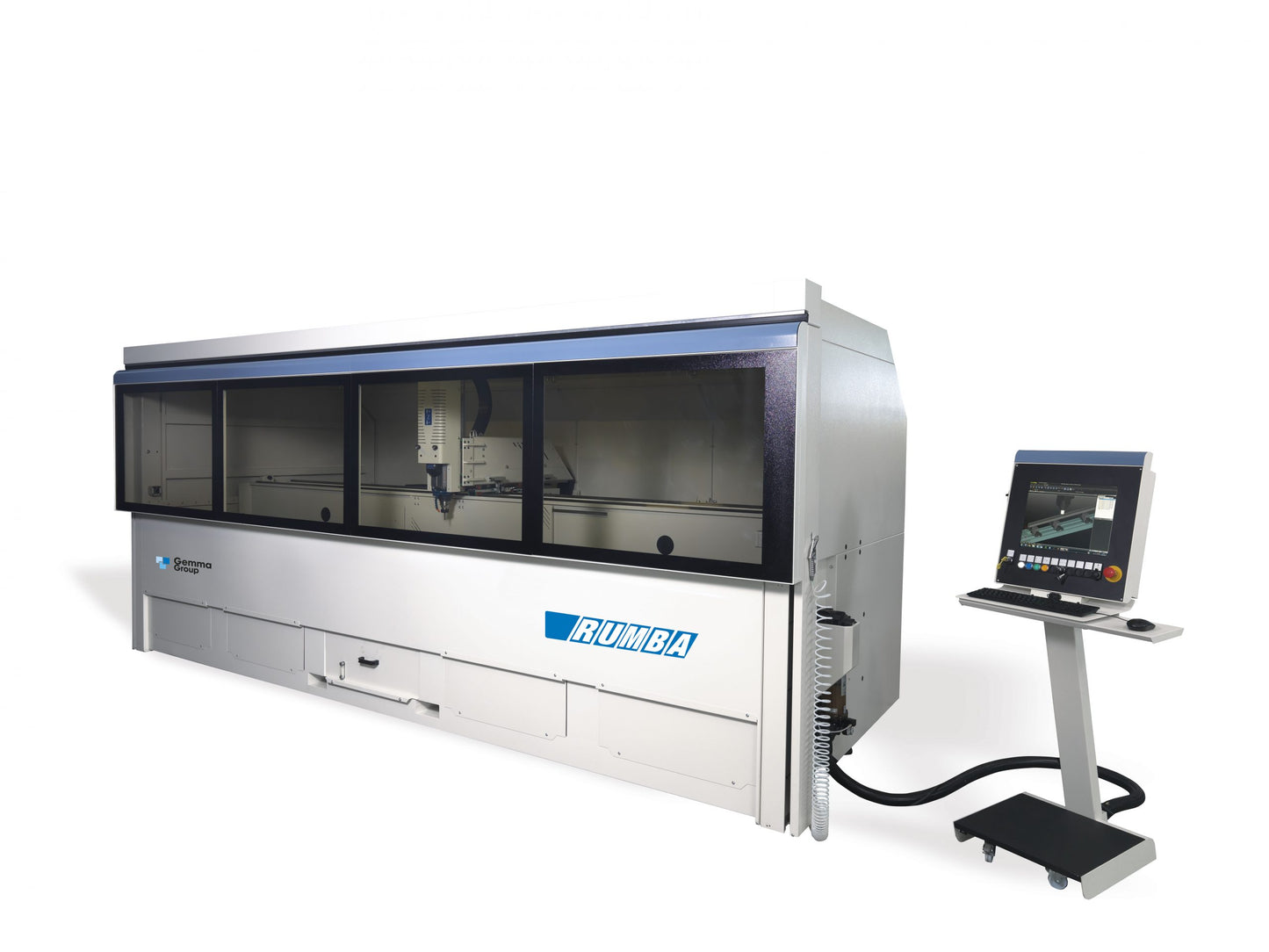

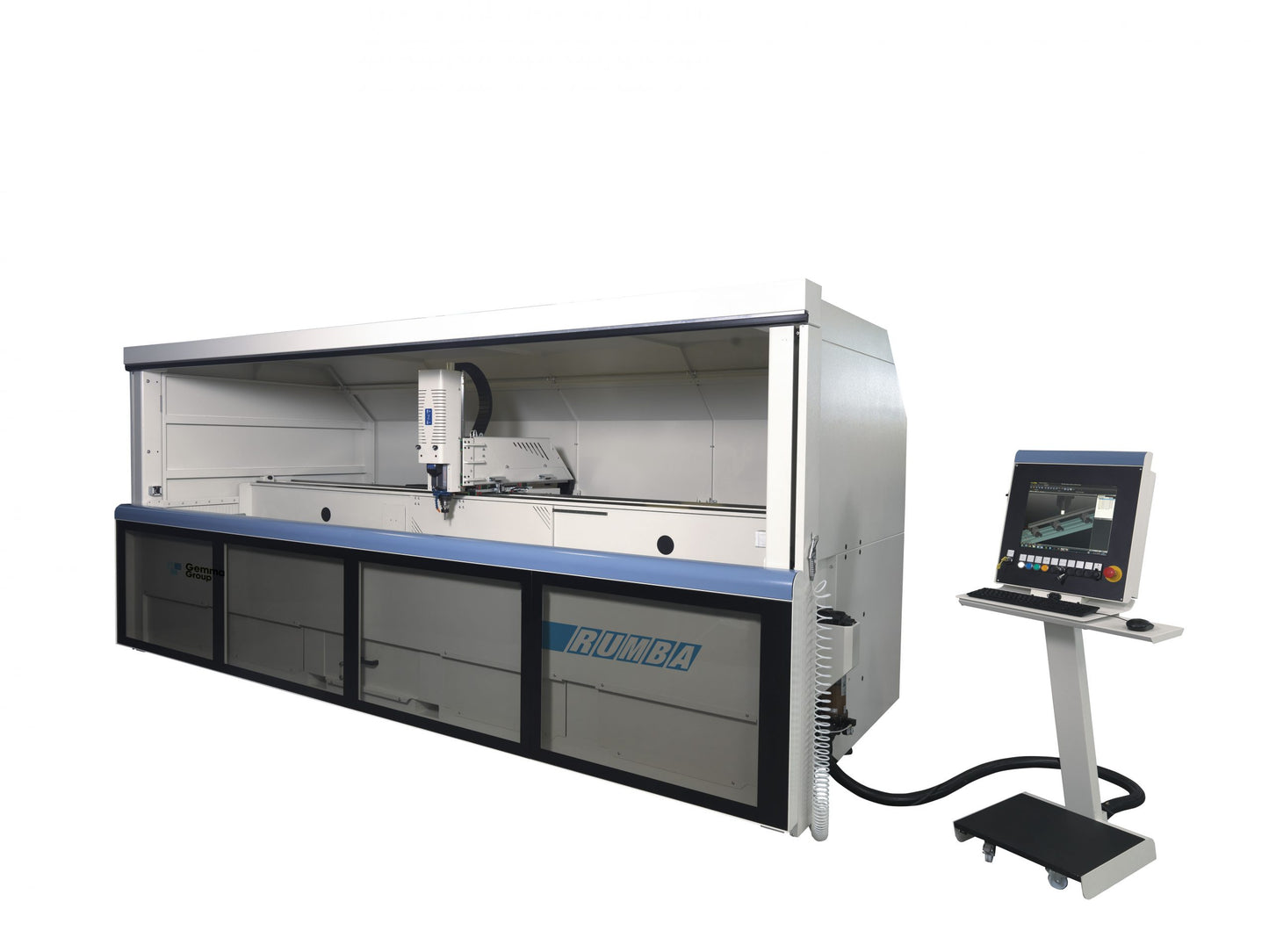

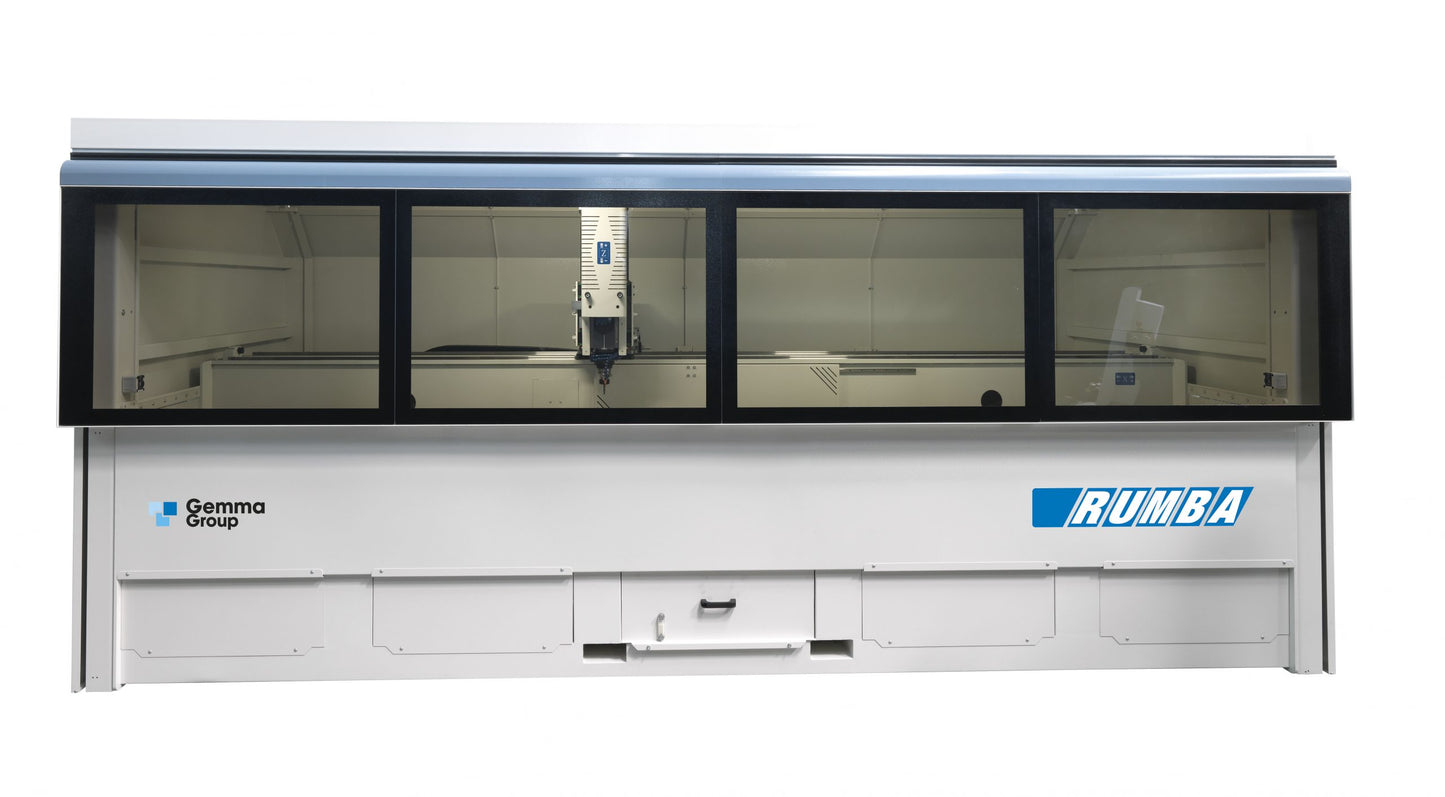

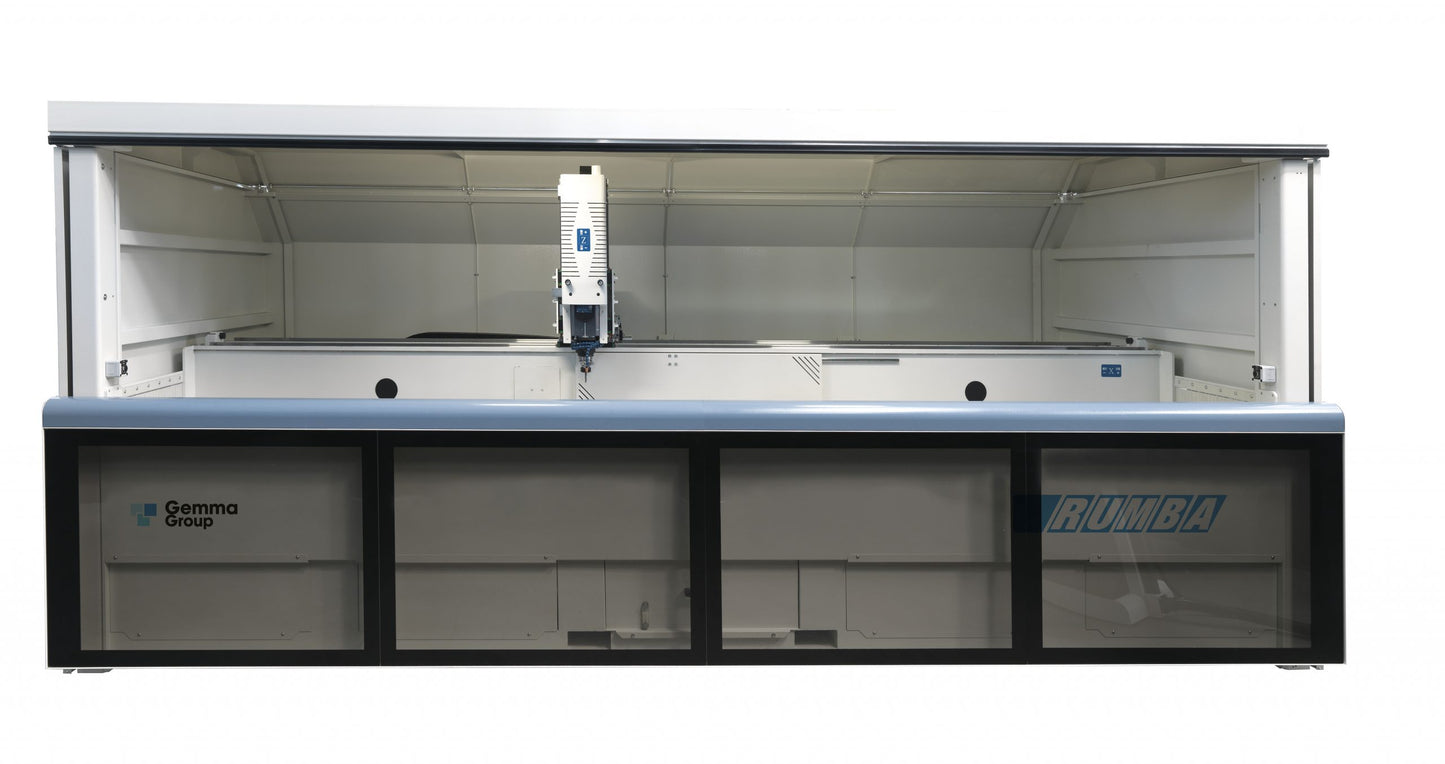

Rumba – 4-Axis CNC Machining Center for Aluminum, Steel & Light Alloys

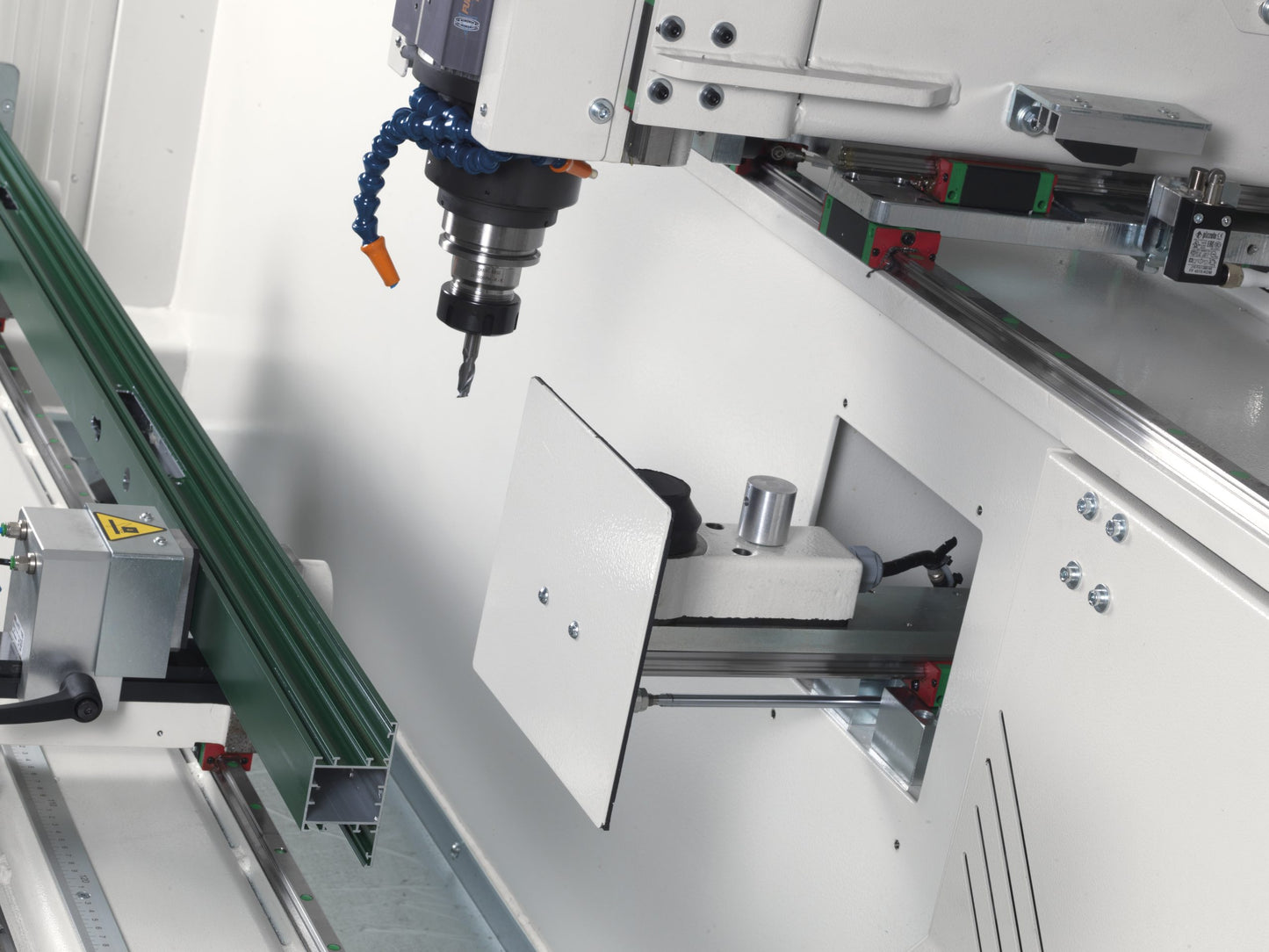

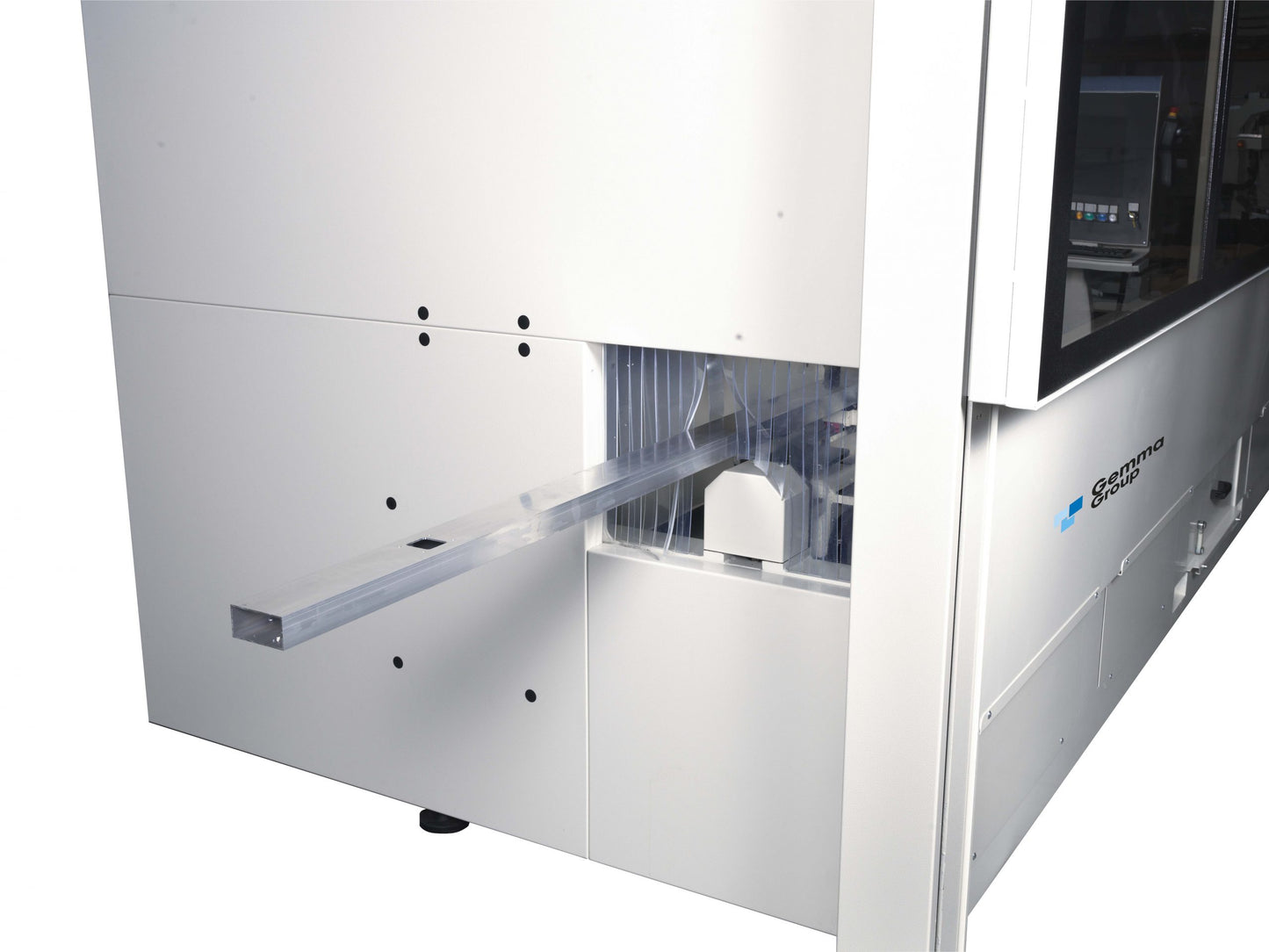

The Rumba 4-Axis CNC Machining Center is a powerful and versatile solution for milling and drilling components made of aluminum, steel, and light alloys. Its robust construction, advanced control system, and automatic tool changer ensure high-quality machining and long-lasting reliability.

Key Features:

- Heavily ribbed electrowelded steel basement with rotating beam and mobile column provides exceptional strength and stability for precise machining.

- Integrated tanks collect swarf, simplifying cleanup and maintaining a cleaner working environment.

- Axes movements are controlled by high-performance brushless motors for accurate and repeatable operations.

- Movement on linear guides with automatic grease lubrication ensures smooth and consistent performance.

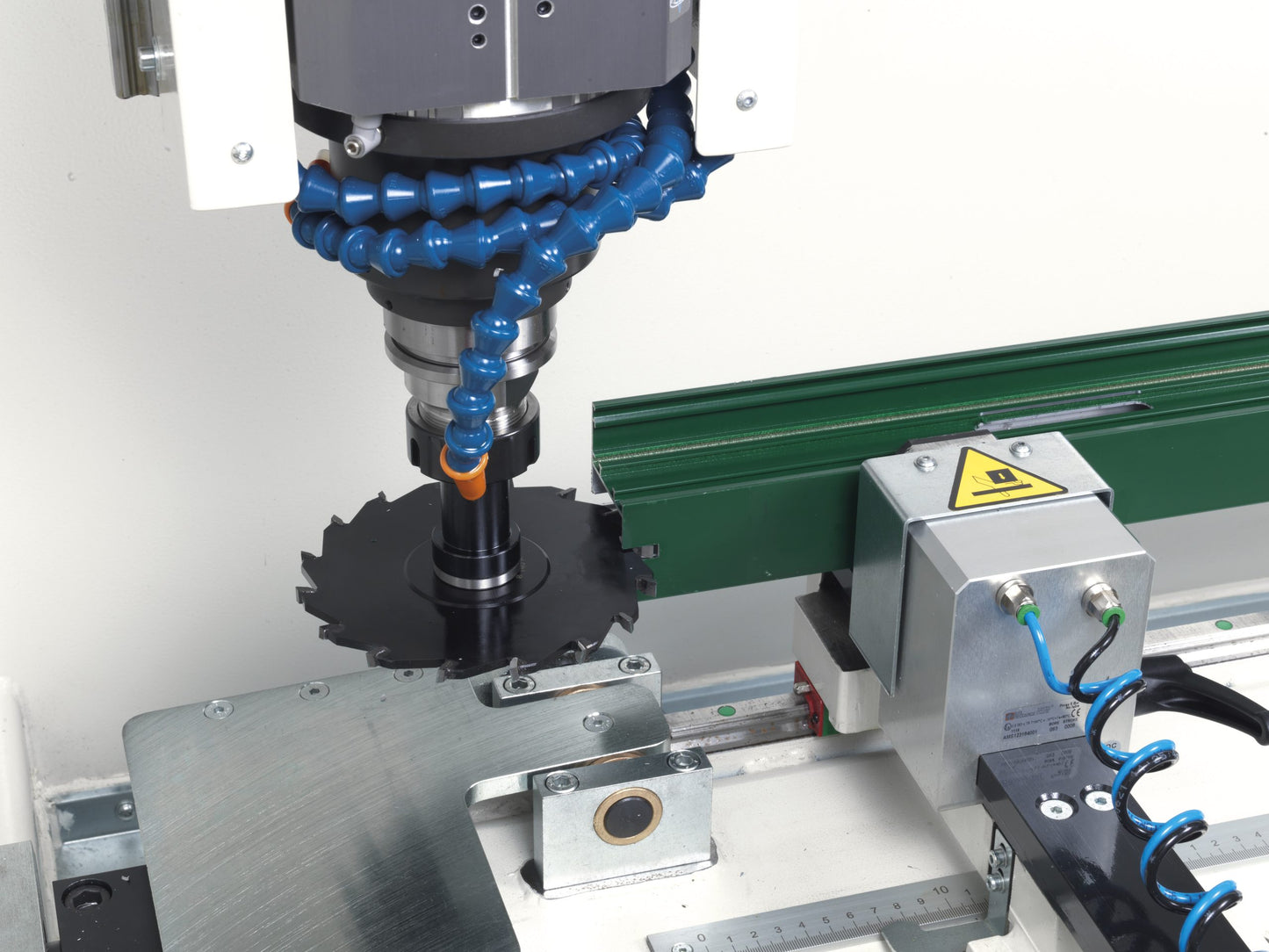

- Compact Electrospindle Group:

- High-precision ceramic bearings lubricated for life, ensuring long-term reliability.

- ISO30 electrospindle taper for secure and accurate tool holding.

- Inverter for precise tool speed selection, optimizing machining for various materials.

- Air cooling for efficient thermal management of the spindle.

- Automatic Tool Changer for maximum flexibility and efficiency in machining operations.

- Versatile Working Area:

- 4 double-action pneumatic clamps securely hold the workpiece.

- Rotating beam controlled by CNC: -90° / 0° / +90° and intermediate degrees for multi-sided machining.

- Advanced Control Panel:

- OSAI control system equipped with the user-friendly HICAM 2 operator interface.

- Intuitive interface for uploading and running machining programs, managing lists, and visualizing workpiece lead time.

- Operator interface on a large 17’’ Windows PC.

- Wi-Fi and teleassistance for remote support and connectivity.

- Meets Industry 4.0’s requirements for modern manufacturing integration.

- Protected Electrical System:** Electrical cabinet with IP 55 protection safeguards components from dust and moisture.

- Effective Thermal Management:** Air-conditioning for the electrical cabinet ensures stable operating temperatures for reliable performance.

- Operator Safety:** Protection cabin for the operator group ensures a safe working environment.

- Compliance:

- Meets CE safety regulations as standard.

- Meets CSA electrical regulations

General Specifications:

| Features | Rumba 3000 (3 M) | Rumba 4000 (4 M) |

|---|---|---|

| Working Area (X) | ~3000 mm | ~4000 mm |

| Electrospindle Power | 4 kW | 4 kW |

| Weight | 2,500 kg | 3,500 kg |

| Dimensions | 4,100 x 2,100 x 2,100 mm | 5,100 x 2,100 x 2,100 mm |

| Pneumatic Clamps | 4 double action | 4 double action |

| Rotating Beam | -90° / 0° / +90° & intermediate | -90° / 0° / +90° & intermediate |

| Control System | OSAI with HICAM 2 | OSAI with HICAM 2 |

Characteristics: 4 Axes CNC Machining Center

Optional Extras:

- "Inox" version: electrospindle 6,6 Kw (S6) HSK63F and water system for lubrication

- Right folding stop

- Full fairing

- Electrospindle 6,6 KW (S6) HSK63F

- Motorized clamps (not for inox version)

- Automatic clamps (moved by spindle)

- Additional manual clamp

- Additional automatic clamp

- Additional motorized clamp

- Bar code reader

- Microdrop lubrication system with pure oil

- Tool length measuring device

- Angular head with blade for 90° cuts

- Oil tank 25 l

- HICAM 3 ADVANCE software license

- Additional HICAM 3 ADVANCE license

- Module to import data in NCX format for HICAM 3

- CAMQUIX software license

- Additional CAMQUIX software license

- Module to import data in Text, XML or CSV for CAMQUIX

- 3D STEP-file detection

- CADXTRACT software license

- Additional CADXTRACT license

- Unilink Rumba (SW)

- Autotransformer for special voltage (230V/480/600V)

Ideal For:

- Milling and drilling components made of aluminum, steel, and light alloys.

- Applications requiring multi-sided machining with the rotating beam.

- Manufacturing environments demanding high precision, automation, and flexibility.

Experience the power and versatility of the Rumba 4-Axis CNC Machining Center!

Share