1

/

of

2

Gemma

MASTER P

MASTER P

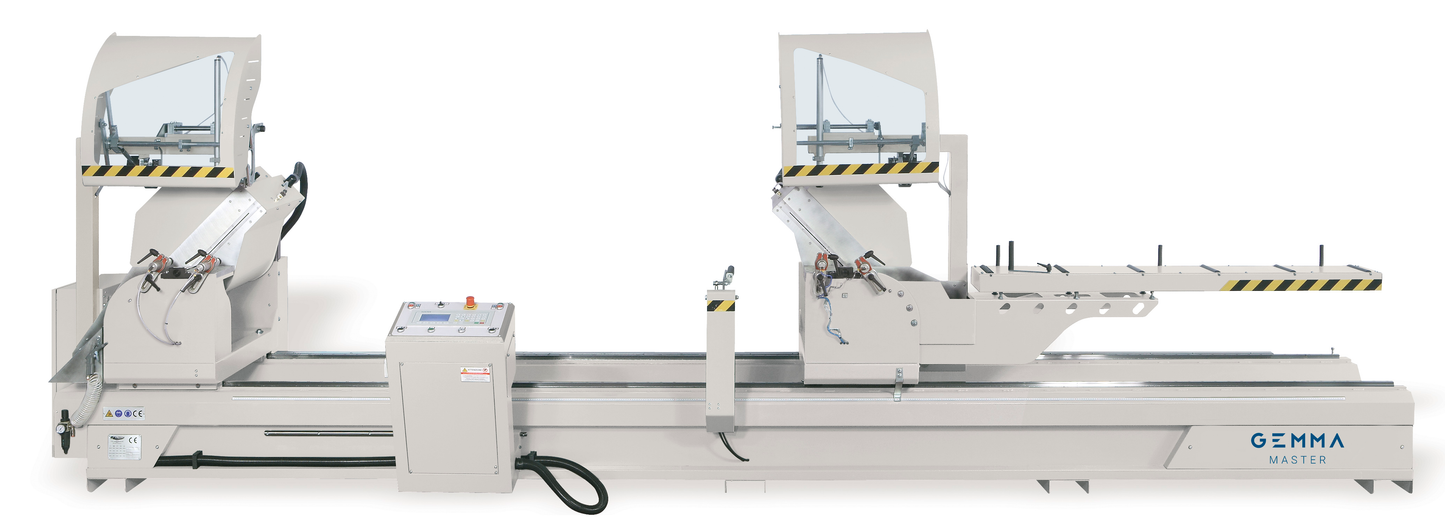

Master P – High-Performance Automatic Double Head Cutting Machine (Ø 600 mm Blades)

The Master P Double Head Cutting Machine is a powerful and precise solution for high-volume profile cutting. Featuring a robust structure, automatic mobile head movement, and software-controlled pneumatic tilting, it's designed for efficient and accurate production in demanding industrial environments.

Key Features:

- Heavy-Duty Construction: Features a stable electrowelded steel basement for maximum rigidity and long-term accuracy.

- Integrated Feeding System: Combines a feeding roller conveyor with the automatic mobile head for seamless material flow and processing.

- Secure Vertical Clamping: Equipped with 4 vertical pneumatic clamps to firmly secure even larger profiles during cutting.

- Precise Axis Control: Axes movements are controlled by brushless motors for high accuracy and repeatability.

- Smooth Mobile Head Movement: The mobile head travels on round guides for consistent and precise positioning along the cutting length.

- Software-Controlled Angle Cutting: Pneumatic tilting for 20°, 45°, 90°, and 135° angles is directly and precisely controlled by the intuitive software interface.

- Efficient Cutting Lubrication: Venturi lubrication system ensures optimal blade performance and extends blade life.

- High-Capacity Blades: Includes 2 high-quality Ø 600 mm blades for increased cutting capacity and efficiency.

-

Advanced Control Panel:

- Latest generation electronic control unit with a user-friendly 10.4” color touchscreen interface.

- Dedicated 1-axis Windows PC for seamless interface and electronic axes management.

- HICAM 2 Software: Powerful and intuitive software for uploading and running complex machining programs, managing cutting lists, and visualizing profile/workpiece data.

- Connectivity options: Ethernet, Wi-Fi, and teleassistance for remote support, diagnostics, and efficient data transfer.

- Network ports: RJ 45 and USB for easy integration into existing network infrastructure.

- Comprehensive Safety: Integral cutting area protections with automatic opening and closing, ensuring a safe working environment and compliance with CE safety regulations.

- Protected Electrical System: Features an electrical cabinet with IP 55 protection for enhanced durability and operational safety.

General Specifications:

- Blade Diameter: 600 mm

- Motor Power (x2): 3 kW

- Machine Weight: 2,550 kg

- Machine Dimensions: 6,400 x 1,700 x 2,150 mm

Cutting Capacity:

| Angle | Cutting Capacity (Width x Height) |

|---|---|

| 90° | 200 x 200 mm |

| 270 x 150 mm / 320 x 100 mm | |

| 45° | 175 x 175 mm |

| 200 x 140 mm / 230 x 100 mm |

Positioning Axis:

- X-axis (Mobile Head Stroke): 5,000 mm

- X-axis Speed: 25 m/min

Cutting Unit Specifications:

- Blade Diameter: 600 mm

- Shaft Diameter: 30 mm

- Blade Revolutions: 2,800 rpm

- Max Cutting Speed: 6 m/min

- Tilting Angles: 20° - 135° (Software Controlled)

- Cutting Angles: 20° - 135°

- Blade Output Management: Oleopneumatic

Cutting Specifications:

- Minimum Cutting Length (between blades): 370 mm

- Maximum Cutting Length (between blades): 5,000 mm

- Under and Oversize Cuts: Possible via software

Power Supply:

- Electric Power: 400 V / 60 Hz (three-phase)

- Air Compressed Supply: 7 Bar

- Air Consumption per Cycle: 57 Nl

-

CSA Compliant

Optional Extras:

- Extension Length 1 m, increasing the maximum cutting length.

- Additional Blade Ø 600 mm.

- Central Intermediate Support for enhanced stability of long or heavy profiles.

- Profile Final Support for improved accuracy on the trailing end of cut pieces.

- Couple of Vertical Clamps for External Cuts, providing additional clamping options for complex profiles.

- Motorized Belt Conveyor for Swarf Removal, automating the removal of cutting waste.

- Automatic Device for Measuring Profile Height, ensuring precise material input and cutting accuracy.

- Fixed Head Roller Conveyor 2.5 m, providing additional support for long profiles on the fixed head side.

- Label Printer for easy identification and tracking of cut pieces.

- Safety Protection with Photocells for an extra layer of operator safety.

- Oil Tank 25 l for extended periods between lubricant refills.

- Autotransformer for Special Voltage (230V/480/600V), ensuring compatibility with various power supply systems.

Ideal For:

- High-volume industrial cutting of aluminum and PVC profiles.

- Applications requiring long cutting lengths and precise angle adjustments.

- Manufacturing environments focused on automation, efficiency, and handling larger profiles.

Elevate your production capabilities with the powerful and versatile Master P Double Head Cutting Machine!

Share