1

/

of

5

Gemma

BOLERO 5

BOLERO 5

Bolero 5 – 5 Axis CNC Machining Center for Aluminum, Steel & Light Alloys

The Bolero 5 is a high-performance 5-axis CNC machining center engineered for precision milling and drilling of aluminum, steel, and light alloy components. Its robust gantry structure, advanced control system, and versatile electrospindle provide exceptional machining quality and long-lasting reliability for complex applications.

Key Features:

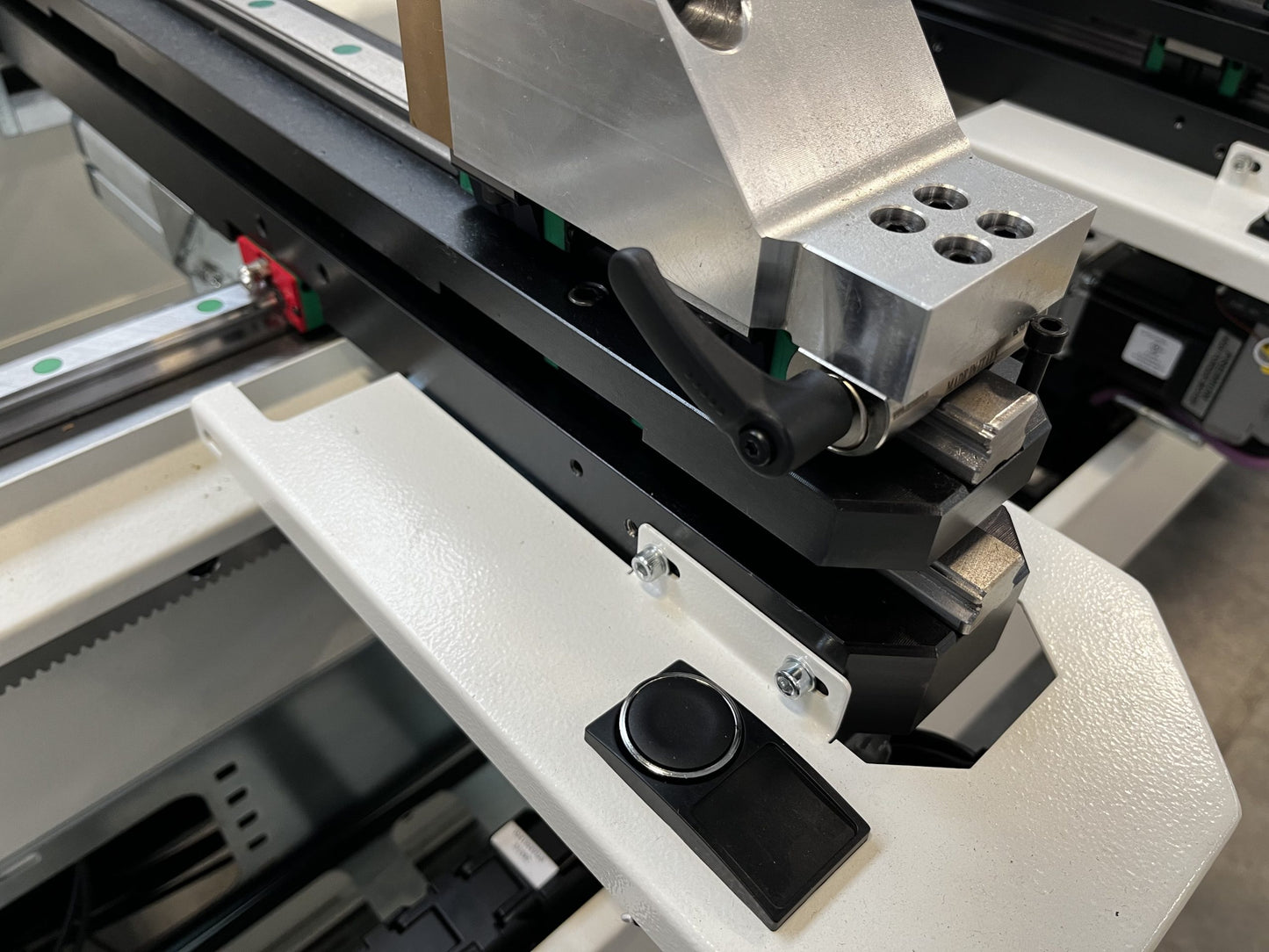

- Heavy-Duty Gantry Structure: Heavily ribbed electro-welded steel basement with an upright bridge-type gantry assembly ensures maximum rigidity and stability for high-quality machining.

- Precise Axis Control: Brushless motors drive movements along precision ball screws and racks on linear guides with automatic grease lubrication, guaranteeing accuracy and smooth operation.

-

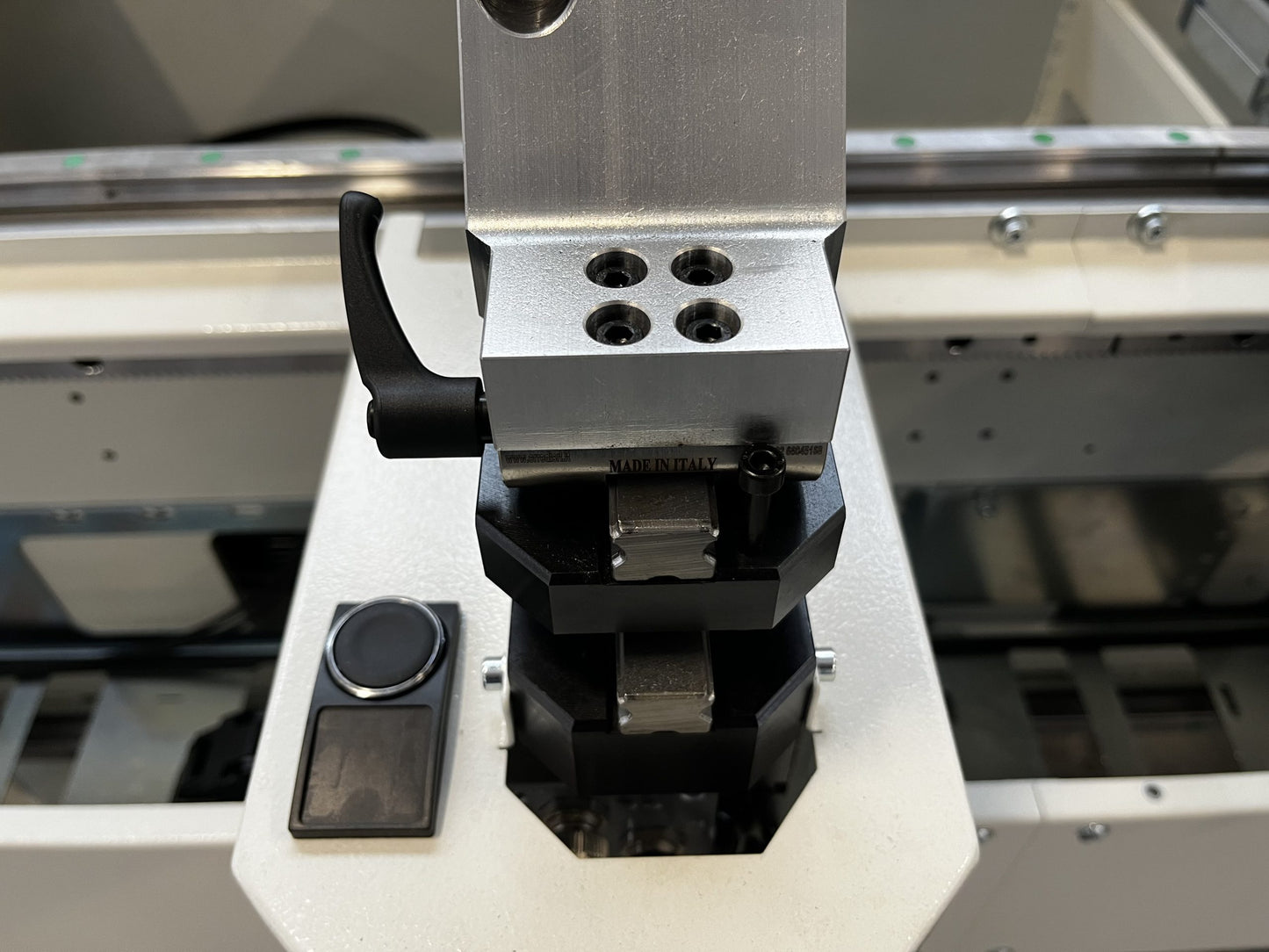

Powerful Electrospindle: Compact electrospindle equipped with:

- High-precision, lifelong lubricated ceramic bearings for smooth and reliable high-speed operation.

- HSK63F electrospindle taper for a strong and precise tool-spindle coupling.

- Inverter for accurate and programmable tool speed selection.

- Liquid cooling system to maintain optimal temperature for enhanced reliability and performance.

- Automatic tool changer for maximum flexibility and efficiency in complex machining sequences (12 positions + 1).

- Microdrop tool lubrication with pure oil for optimal cutting performance and tool life.

-

Large Working Area:

- 8 pneumatic clamps with motorized shifting controlled by CNC for secure and flexible workpiece holding.

- Left stop for precise material positioning.

-

Advanced Control Panel:

- OSAI control system equipped with the intuitive HICAM 2 operator interface for easy uploading and running of machining programs.

- List machining and real-time visualization of workpiece/profile data on a 17” Windows PC.

- Wi-Fi and teleassistance capabilities for remote support, diagnostics, and efficient data transfer.

- Meets Industry 4.0 requirements for seamless integration into modern manufacturing environments.

- Robust Electrical Cabinet: IP 55 protection and an integrated air-conditioning unit ensure reliable operation in demanding industrial conditions.

-

Comprehensive Safety System:

- Full protection cabin for the operator group.

- Photoelectric barriers to protect the working area.

- Perimeter protection around the machine.

- Complies with stringent CE safety regulations.

General Specifications:

- Electrospindle Power: 17 kW (S6) / 15 kW (S1 Continuous)

- Maximum Blade Diameter: 500 mm

- Machine Weight: 5,400 / 5,800 kg

- Machine Dimensions: 10,950 x 4,100 x 2,950 mm

Working Area: 6,900 / 9,400 mm (X Axis Useful Working Field) x 1,300 mm (Y Axis Stroke) x 670 mm (Z Axis Stroke)

Orthogonal Axes (Y-Z):

-

Y Axis (Transversal) Stroke: 1,300 mm

- Speed: 53 m/min

- Acceleration: 2 m/s²

-

Z Axis (Vertical) Stroke: 670 mm

- Speed: 35 m/min

- Acceleration: 1.3 m/s²

Pivoting Axes (A-C):

-

A Axis (Pivoting Angles): +/- 135°

- Speed: 6.1 m/min

- Acceleration: 1.5 m/s²

-

C Axis (Pivoting Angle): +/- 320°

- Speed: 9.3 m/s²

- Acceleration: 0.5 m/min

Positioning Accuracy: ± 0.2 mm Positioning Repeatability: ± 0.1 mm

Electrospindle Group:

- Electrospindle Taper: HSK63F

- Bearing Lubrication: Lifelong Ceramic Bearings

- Rotation Speed (with Inverter): 1,000 - 24,000 rpm

- Automatic Tool Change Magazine: Carousel, 12 positions + 1 (blade)

- Maximum Cone Length + Tool: 160 mm

- Maximum Cone Weight + Tool: 10 kg

- Tools Included (Standard): 4

- Holder Clamp Cones Included: 6

- Blade Ø 500 mm Included: 1

Power Supply:

- Electric Power: 400 V / 50 Hz (three-phase)

- Compressed Air Supply: 7 Bar

- CSA Compliant

Optional Extras:

- 76.14.01: Extension Length 2.5 m, increasing the X-axis useful working field.

- 76.14.02: Extra Couple of Motorized Clamps for enhanced workpiece holding.

- 76.72.21: Right Stop for Pendulum Machining, enabling efficient processing of multiple parts.

- 76.13.01: Double Central Stop for optimized material positioning.

- 76.12.10: Bar Code Reader for quick and accurate program loading.

- 76.13.31: Motorized Belt Conveyor for Swarf Removal, automating waste management.

- 76.14.04: Tool Length Measuring Device for precise tool calibration.

- 76.72.22: Touch Probe for accurate workpiece measurement and setup.

- 76.72.23: Cut and Separate for Pendulum Mode, automating the separation of machined parts.

- 76.72.24: RTCP Device for the Operator Group Axes' Realignment, ensuring continuous accuracy.

- 76.80.24: Integral Cover with Predisposition for Suction Connection, enhancing dust and chip extraction.

- 76.11.33: Oil Tank 25 l for extended lubrication cycles.

- 76.14.05: HICAM 3 ADVANCE Software License for advanced programming capabilities.

- 76.72.27: Additional HICAM 3 ADVANCE License.

- 76.14.06: Module to Import Data in NCX Format for HICAM 3.

- 76.14.07: CAMQUIX Software License for alternative programming solutions.

- 76.14.08: Additional CAMQUIX License.

- 76.14.09: Module to Import Data in Text, XML or CSV Formats for CAMQUIX.

- 76.14.10: 3D STEP-file Detection CADXTRACT Software License for advanced CAD/CAM integration.

- 76.14.11: Additional CADXTRACT License.

- 76.72.26 / 76.72.21: Autotransformer for Special Voltage (on request).

Ideal For:

- High-precision milling and drilling of complex components.

- Applications in aerospace, automotive, and general engineering.

- Manufacturing environments demanding 5-axis simultaneous machining capabilities.

Unlock unparalleled machining potential with the Bolero 5 – 5 Axes CNC Machining Center!

Share